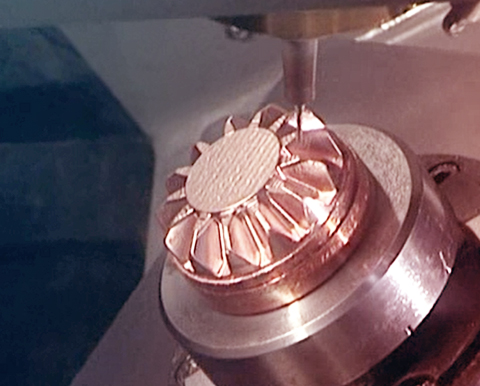

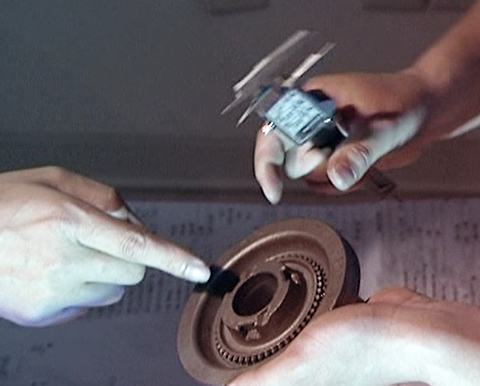

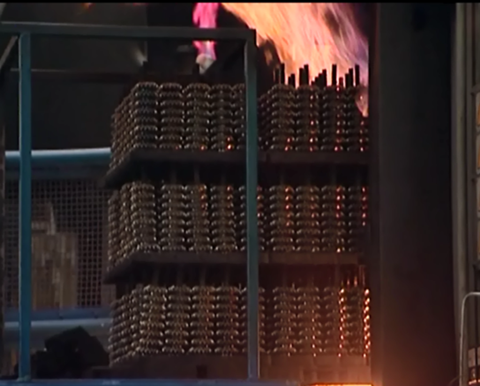

公司是一家具有自主创新能力、拥有自主知识产权、掌握先进的齿轮模具设计开发与制造核心技术、采用冷温热精密锻造成形技术、专业化制造汽车齿轮的高新技术企业、国家火炬计划重点高新技术企业、中国齿轮行业协会50强最具品牌影响力企业、江苏省经济和信息化委员会两化融合研发设计示范企业。公司建有企业技术中心、博士后科研工作站、省级工程技术研究中心、江苏省近净成形用长寿命模具设计工程技术研究中心和江苏省塑性成形与高精度模具设计制造工程中心,与华中科技大学、上海交通大学、武汉理工大学、北京机械科学研究总院建有紧密的产学研合作关系,并成为首批国家级工程实践教育中心建设单位。公司现拥有授权专利83件,其中PCT国际发明专利4件、国家发明专利24件,实用新型专利55件。多项研究成果获国家、省(部) 级科技进步奖...

Copyright 2017 Reserved By PACIFIC PRECISION FORGING 浙ICP备09074515号